MES Systems for Pharma and Dispensing Systems Manufacturer

This case study explores the implementation of Manufacturing Execution Systems (MES) tailored for both large and small pharmaceutical manufacturing plants. It highlights the objectives, solutions, components, and business value delivered through the integration of these systems, as well as the future vision for enhanced operational efficiency.

Primary Objective

Our goal was to implement Manufacturing Execution Systems that cater to the unique needs of both large and small pharmaceutical manufacturing plants, ensuring streamlined operations and improved production management.

Industry Focus

This solution serves the manufacturing and distribution sector, where efficient production processes and effective production insights are crucial for success.

Solution Overview

We designed two distinct systems to meet the varying requirements of different plant sizes:

EDGE: A compact MES system specifically designed for smaller-scale plants, offering essential functionalities without the complexity of larger systems.

- MES: A comprehensive production order automation system tailored for larger facilities, providing advanced features for efficient manufacturing execution.

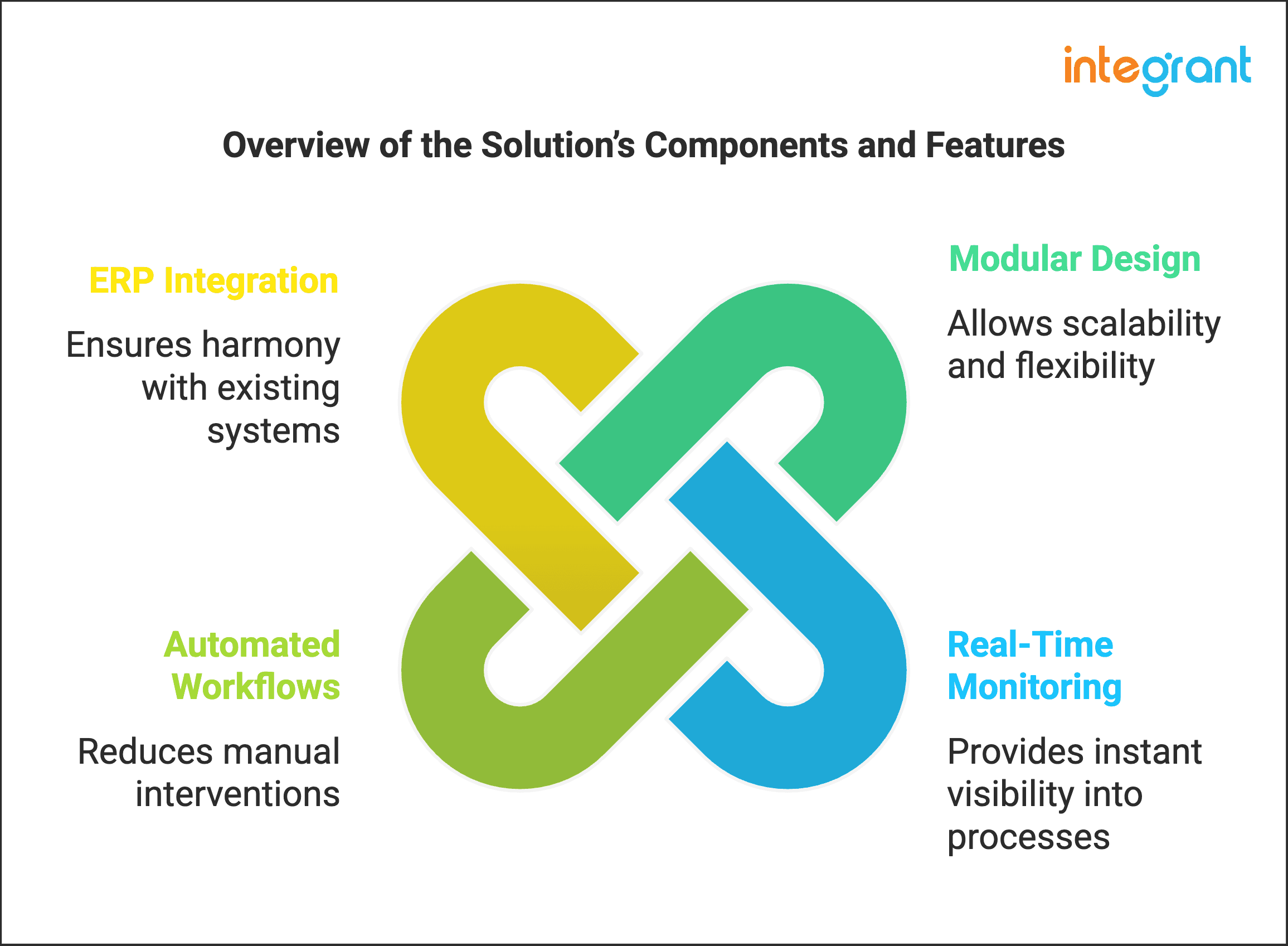

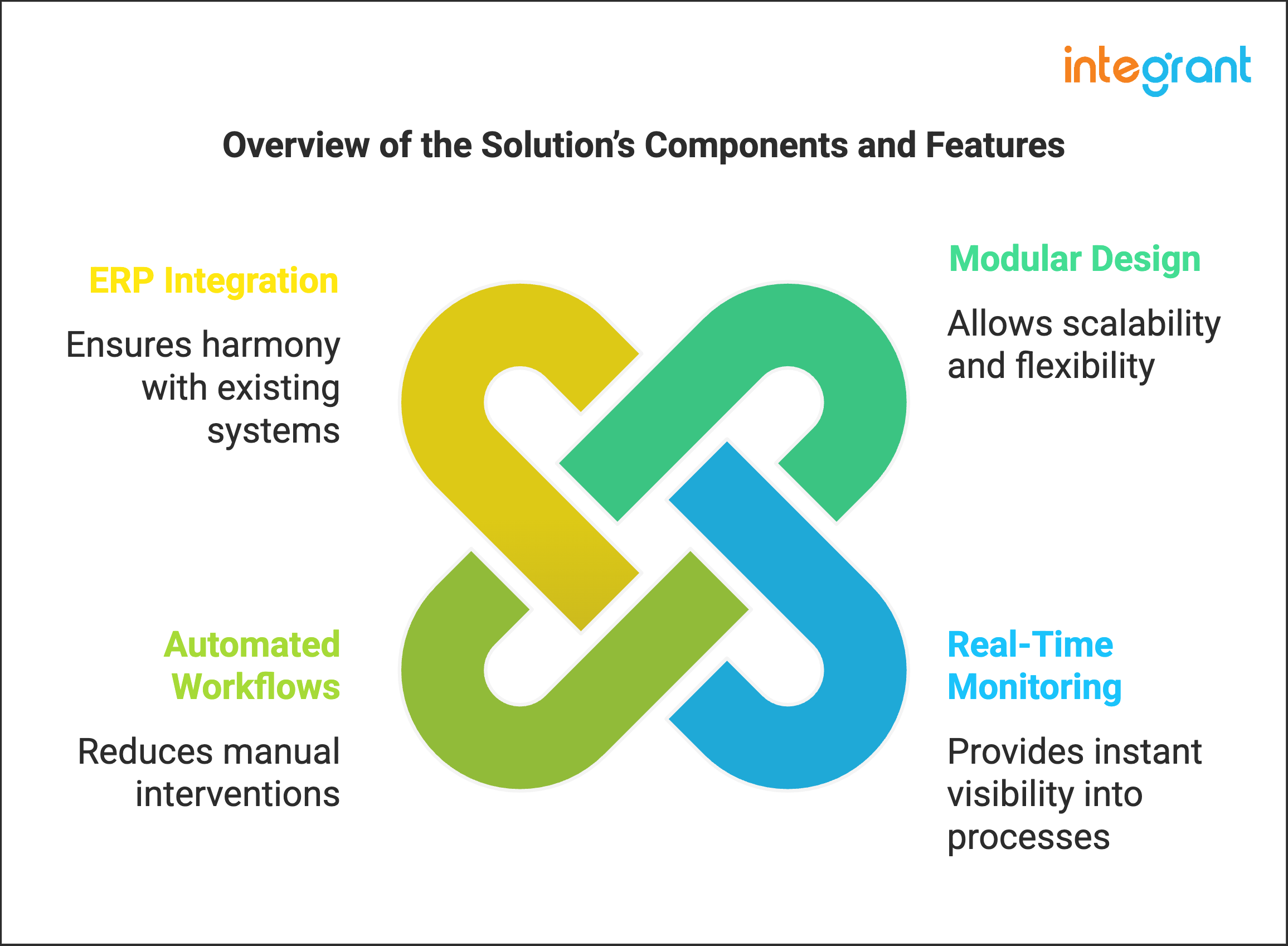

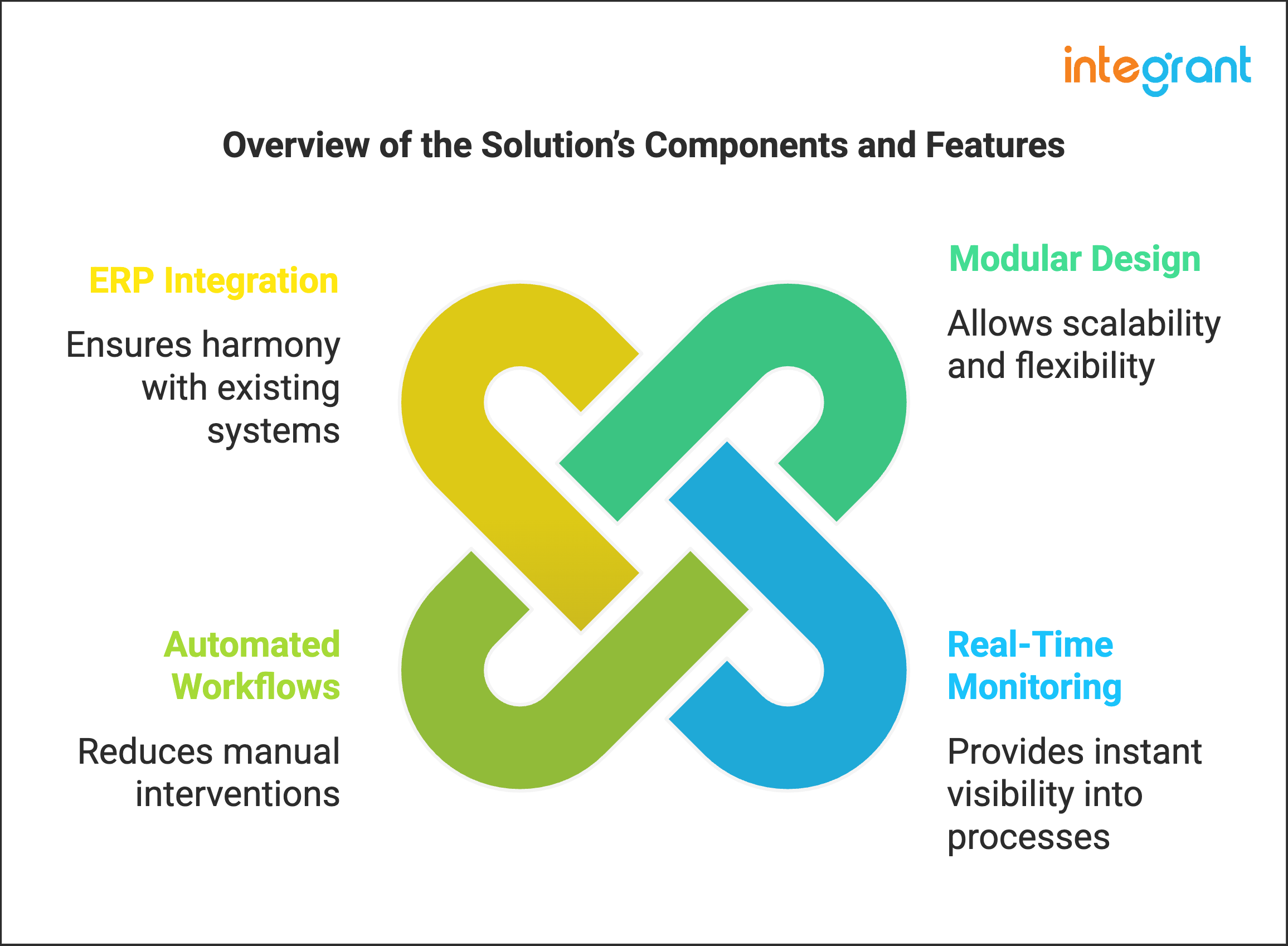

Solution Components & Features

The MES solution features a modular design that can be customized according to the scale of the plant:

- Modular MES Design: Allows for scalability and flexibility, enabling plants to adopt features as needed.

- Real-Time Production Monitoring and Reporting: Provides instant visibility into production processes, facilitating timely decision-making.

- Automated Production Workflows: Reduces the need for manual interventions, enhancing efficiency and compliance with industry regulations.

- Seamless Integration with Existing ERP Systems: Ensures that the MES can work in harmony with current enterprise resource planning systems, maximizing the value of existing investments.

Business Challenges Solved

The implementation of the MES systems effectively addressed several critical business challenges:

- Streamlined Manufacturing Execution: The MES facilitates smoother production management processes, reducing bottlenecks and delays.

- Reduced Manual Interventions: Automation of workflows minimizes human error and enhances operational efficiency, ensuring compliance with stringent pharmaceutical regulations.

Business Value Delivered

The implementation of the MES systems has resulted in significant business value:

- Reduced Production Time: Streamlined processes have halved the time required to complete production cycles.

- Improved Time-to-Market for Pharmaceutical Products: Faster production translates to quicker delivery of essential medications to the market.

- Saved Operational Costs: Automation of workflows has led to substantial cost savings, allowing resources to be allocated more effectively.

Future Vision

Looking ahead, the vision for the MES systems includes:

- Integration of IoT Devices: Enhancing the MES with IoT technology for real-time production tracking and data collection.

- AI-Powered Analytics: Utilizing advanced analytics to monitor production performance, identify bottlenecks, and optimize processes.

- Predictive Maintenance Capabilities: Developing systems that can predict equipment failures, thereby minimizing downtime and maintaining continuous production flow.

In conclusion, the implementation of tailored MES systems for pharmaceutical manufacturing plants has proven to be a transformative initiative, driving efficiency, compliance, and cost savings while setting the stage for future advancements in production technology.

Ready to Transform Your Manufacturing Operations?

Let's discuss how our tailored MES solutions can help you achieve similar results. Our team of manufacturing technology experts will work with you to understand your unique challenges and design a solution that fits your specific needs. Contacts us.